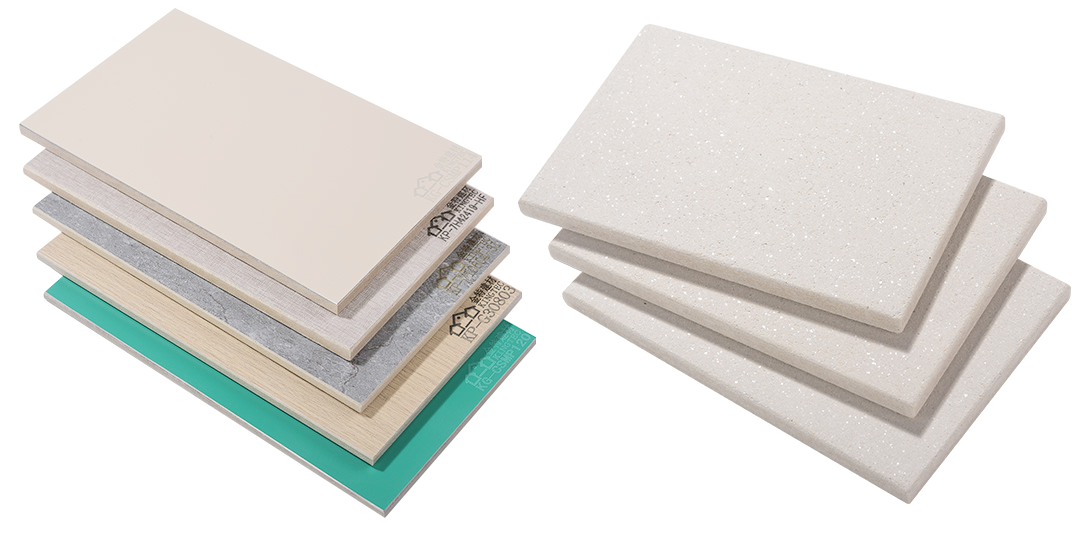

870 Hawkpan

975 Hawkpan

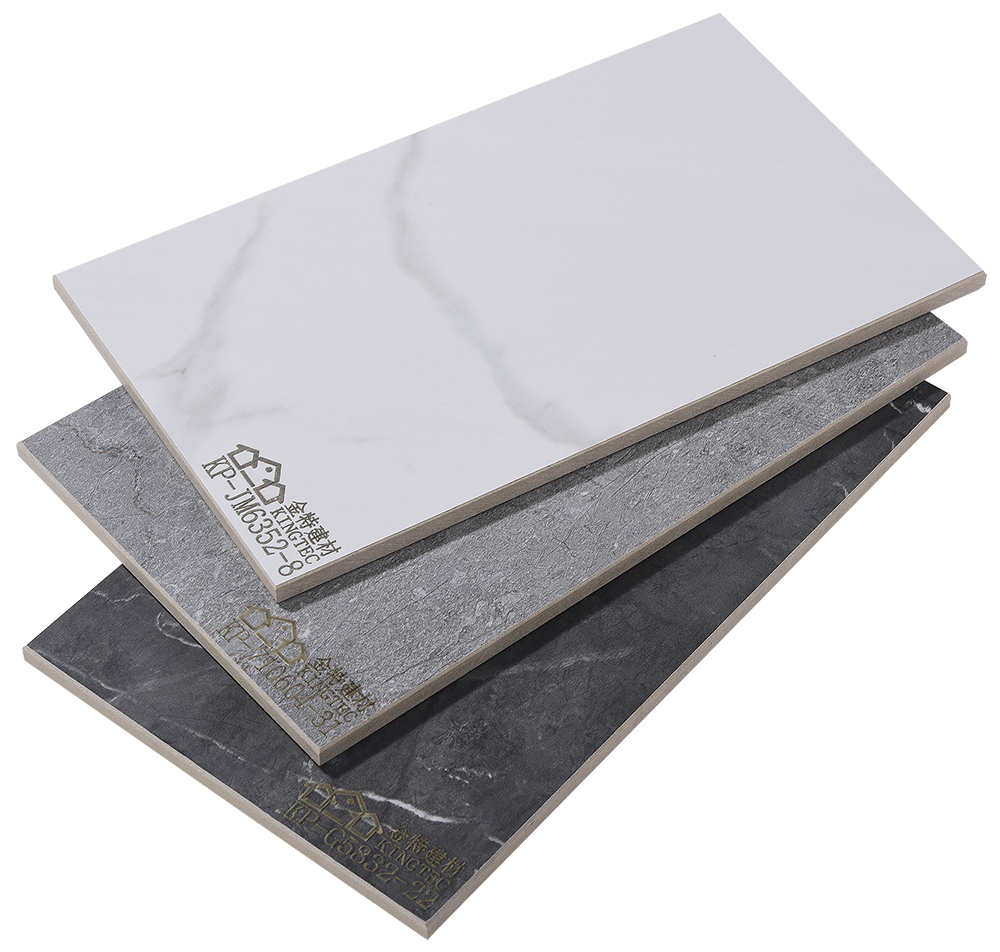

Hawk-X Panel

Based on the international leading technical formula, KingTec factory adopts KTN360process to add a variety of fire prevention components and corresponding minerals toresearch, develop, then produced a high grade professional fire proof calcium silicateboard according to the requirements of passive fire protection systems.

Smoke Toxicity:Comply with GB/T20285-2006, AQ Security Level

Asbestos Content:Comply with HJ/T223-2005 Standard, asbestos free

Radioactivity:Internal Exposure Index IRa≤0.20; External Exposure Index Ir≤0.25

Grade A decoration materials, unlimited production, marketing and

application range

Based on the international leading technical formula, KingTec factory adopts KTN360process to add a variety of fire prevention components and corresponding minerals toresearch, develop, then produced a high grade professional fire proof calcium silicateboard according to the requirements of passive fire protection systems.

Smoke Toxicity:Comply with GB/T20285-2006, AQ Security Level

Asbestos Content:Comply with HJ/T223-2005 Standard, asbestos free

Radioactivity:Internal Exposure Index IRa≤0.20; External Exposure Index Ir≤0.25

Grade A decoration materials, unlimited production, marketing and

application range

Bending Strength (Dry) Mpa:≥5.5

Impact Resistance KJ/m²:≥1.0

Hawk-X Pressure Relief Board is made of calcium material, siliceous material and plant fiber. It was made by molding,high temperature and autoclave curing, then formed stable tobermorite crystal structure. Kingtec Hawk–X pressurerelief system releases blast pressure rapidly without secondary injury.

1.Standard Size mm:2440 X 1220 X 9/10/12

2.Density g/cm³:1.10±0.1

3.Water Content Rate %:≤10

4.Water Expansion Rate %:≤0.20

5.Thermal Conductivity W/(m.k):≤ 0.20

6.Bending Strength (Dry) Mpa:≥8

7.Bending Strength in Saturated Sate Mpa:≥5.6

8.Impact Resistance kj/m:≥1.0

9.Smoke toxicity:Comply with GB/T20285-2006, AQ Security Level

10.Mould Resistance:Comply with HG/T3950-2007, Grade 0

11.Asbestos Content:Comply with HJ/T223-2005 Standard, asbestos free

12.Radioactivity:Internal Exposure Index IRa≤0.20; External Exposure Index Ir≤0.25

Grade A decoration materials, unlimited production, marketing and application range

Frost Resistance:100 freeze-thaw cycles, no cracking, no delamination, no falling off

13.Water Impermeability:24hrs test, no water-drop

14.Non-combustibility:Comply with GB8624-2006 Grade A1

15.Hot Water Performance:Flexural Strength Ratio

16.Soaking Drying Performance:After 25 cycles, the ratio of flexural strength ≥65%

17.Water Resistance:After 30 days of test, no crack, no delamination, no shedding, no swelling, no discoloration

18.Acid Resistance:After 15 days of test, no crack, no delamination, no shedding, no swelling, no discoloration

19.Alkali Resistance:After 15 days of test, no crack, no delamination, no shedding, noswelling, no discoloration

The pressure relief component is set in the reasonable part of the building, so that when the indoor explosion occurs, thepressure relief component can instantly release the critical pressure, guide the orderly release of the explosive force,reduce the impact on other parts in the explosion process, and at the same time, by controlling the quality and propertiesof the explosive fragments, it can effectively reduce the occurrence of personal injury and property loss caused by theexplosive shock and the explosive fragments Probability.